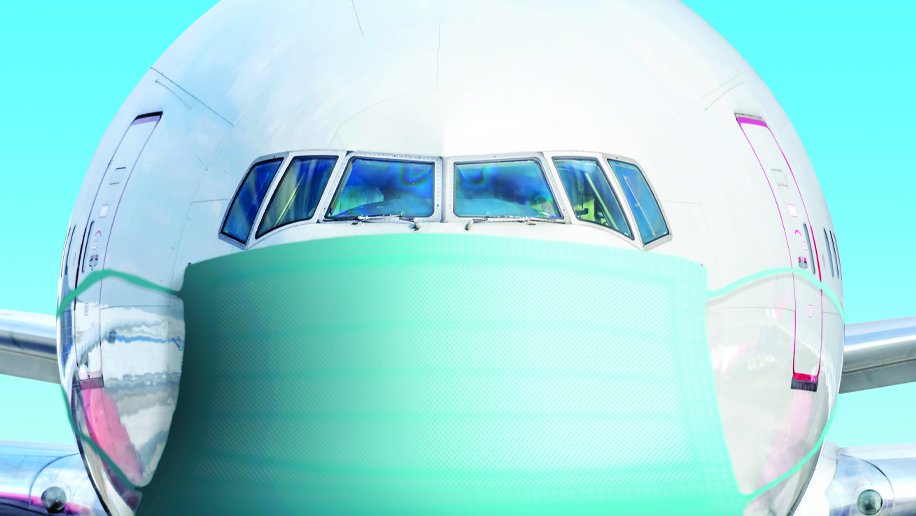

As the coronavirus continues to take travel to unprecedented depths, there may be an upside to this tale afterall: Flying has never been cleaner. Airlines, airports and aircraft manufacturers are going to extraordinary heights to ratchet up the confidence measures it will take to get travelers to take to the skies, even as the coronavirus continues to rage on the ground.

Research from the International Air Transport Association (IATA) shows that just 45 percent of travelers are willing to return to airports these days. Some 58 percent of those surveyed said that they have successfully avoided air travel, with 33 percent suggesting that they will continue avoid travel in future as a way to reduce their risk of catching COVID-19.

“If anything, consumers have actually got rather more cautious and we have a majority saying now that they would wait more than six months before traveling,” IATA chief economist Brian Pearce told Bloomberg News. “The survey is telling us that passengers are rather cautious.”

The Air Up There

The air on a plane remains one of the top concerns for flyers. Breathing is now a contact sport with all sorts of consequences built in. Are airlines safe to sit in for five or six hours at a clip, often packed like fruit heading for market? Are masks still necessary to wear onboard? What if the person behind you has a fever a smidge lower than the allowable degree? What if the person in the middle seat starts coughing? Should you touch the seatback button or use the tray table?

Airlines are claiming that flying has never been cleaner or safer and, in many ways, they are right. But then we have never had a virus like the novel coronavirus.

In an effort to quell fears and answer those questions that can be answered, Boeing’s Product Marketing Director, Jim Haas recently spoke to the fact that the air circulation inside a typical aircraft is, indeed, clean and has been that way since the mid 1990s when HEPA filters were introduced. The filters are medical grade, often used in hospital isolation chambers and operating rooms to scrub the tiniest particles – including viruses – from the air with 99.9 percent+ effectiveness. The HEPA filters have not been tested with the COVID-19 virus per se but have been tested with particles the size of the virus and deemed extremely effective at removal of particulate matter. A new measure that is being recommend to airlines at this time, according to Boeing, is to maximize cabin airflow / HEPA filtration not only during flight, but also on the ground to filter cabin air during passenger boarding and deplaning.

But it is not just the air moving through the filter, it is also the air in its flow path that makes flying into a reasonable risk to take.

“A key point that many passengers do not understand is the direction the air flows,” said Haas. “Many think the air flows from front to back. It does not. It comes in from the top, comes down onto the seat and exits out, and there is continuous ventilation in the cabin. Cabin air is exchanged every two to three minutes, which is much faster than office buildings and other interior spaces where people go. We designed it specifically to do this. And it is one of key points we want people to understand.”

Aircraft makers, including Boeing, Airbus and Embraer are working together and sharing notes on what is working and what is not to optimize the air quality inflight. Haas notes that this part of the business is not a competition. There is too much at stake. But he also notes that the systems have been in place for some 25 years so it is not the technology that is new when it comes to air filtration. What is new is the disinfecting practices ahead of boarding coupled with the temperature monitoring of passengers at the gate.

Coating the Cabin

To that end, airlines are looking at disinfecting practices and devices that could be instrumental in killing bacteria and viruses from all surfaces passengers touch giving each passengers a completely sanitized environment on takeoff.

Among those approaches are the use of sanitizing chemicals, including Purell-like liquids proven to be safe for humans, non-toxic or and not harmful to furnishings and equipment and completely deadly to viruses, bacteria and fungi. Periodic spraying of anti-microbial coating is also necessary to create a hostile environment for lingering germs that may not die so quickly.

Then, new ways of dispatching ultra violet rays have been deployed to destroy lingering unseen enemies on textiles and other surfaces. Boeing has been beta-testing a portable wand that evenly radiates the deadly UV rays on a front to back sweep of the empty aircraft before passengers board. A built-in UV solution for disinfecting bathroom areas is now in the prototype stage as well, but because that involves a structural change for inflight use, regulatory approvals are necessary and, likely, years away.

“We are working with a variety of industries, such as IATA, and other airline manufacturers, the ICCAIA(International Coordinating Council of Aerospace Industries Associations) and we are working with airports – what happens at airport is one of the first layers of travel. It is important for travelers to have a consistent experience country to country. We are also working with researchers and academia to check our modeling and make sure the way we understand the virus lines up with what everyone else understands,” said Haas.

“We see the necessity of having a multilayered approach to protect the passenger during the entire journey: from home to airport to departure to in the cleaning and disinfecting and all the tech in place — and then there is the cabin experience inflight. Air cleaning and filtration, arrangements of seats and role of face masks – all put together – makes flying safe.”

Haas notes that HEPA filters can only clean the air that circulates through them, so if a passenger sneezes and there is no filter between the person and other passengers, the filter cannot clean that air. That is why in the current health emergency it’s important to work across the industry on using additional protections—such as face masks—that further help mitigate risks, he says.

While, each airline must adopt its own policies, airline manufacturers like Boeing and Airbus do much of the heavy lifting to make sure the craft interior has all the structural advantages required for flying safely during COVID times and that airline customers have the research and tested recommendations by which to model their policies.

For instance, Singapore Airlines is assuring that all lavatories feature contactless faucets and have anti-bacterial hand wash. SIA is also looking at a trial of an ultra-violet light cleaning procedure on the ground for its lavatories before every flight. To give passengers added reassurance, the airline now provides all passengers with a Care Kit that includes a surgical mask, anti-bacterial hand wipes and hand sanitizer.

As for seat distancing as a prophylactic against exposure, some airlines are pledging to uphold middle seat vacancies while others are not, suggesting such a financially crippling move for an airline is more of a PR stunt than a proven protection against contracting the virus. United and American Airlines have eschewed the practice while other airlines, such as Southwest, Delta and JetBlue, have committed to block all or some seats for social distancing assurances, at least for a time. Sen. Bernie Sanders and federal health officials criticized American Airlines recently for altering policy toward booking flights to capacity.

Currently, there are no federal requirements to distance travelers on commercial aircraft. Nor is there a federal mandate guiding the wearing of masks inflight. In early July, the Departments of Homeland Security, Transportation, and Health and Human Services jointly issued guideline recommendations for the air travel industry in a document called the “Runway to Recovery.” However, enforcement of those policies remains entirely in the hands of each airline.

From Gateway to Gate

Airports, too, have been vigilant in taking a stand against the coronavirus with a variety of measures that have been rolled out at airports around the world.

Airports, such as Los Angeles International Airport (LAX) – a prime gateway to Asia from the U.S. and the world’s third busiest airports just behind Atlanta’s ATL and Beijing’s PEK, initiated the COVID-19 Recovery Task in April, which includes a new program using thermal camera technology, along with many other technologies aimed at ensuring the health and safety of travelers. The airport is also piloting new UV disinfecting technology on select escalator handrails and in restrooms to test the technology and its overall effectiveness, and it continues to amass information on the thermal camera pilot that is ongoing in the Tom Bradley International Terminal. For arriving passengers, staff from the Centers for Disease Control and Prevention (CDC) have been at LAX for months following the federal mandates for passenger screening. Passengers on international flights pass through the thermal camera pilot and may be referred to the CDC for additional screening.

“The safety and security of our guests and employees has always been our first priority, and since the global pandemic began Los Angeles World Airports has been working nonstop to update our policies, procedures and physical spaces to help prevent the spread of COVID-19,” said Justin Erbacci, interim Chief Executive Officer, Los Angeles World Airports (LAWA). “Passengers will have a different traveling experience for the foreseeable future.”

Some airports are looking at more focused and individualized ways to make sure the mighty germ does pass a single boundary. To manage this feat, airports such as Hong Kong International Airports and now international airports in Mexico, such as Guadalajara International (GDL), are using CLeanTech sanitation pods.

These pods are small rooms about the size of a small shed or elevator compartment, with windows. The structure is coated with an antimicrobial material and uses a technology called UV photocatalysis to kill viruses, bacteria and pathogens that may be lurking on the person in the pod. For good measure, the booth dispenses a safe sanitizing mist to disinfect clothing and carryon items as well.

Grupo Aeroportuario del Pacífico, the airport management company that operates GDL and 13 other airports in Mexico and the Caribbean, is testing three of the

CLeanTech disinfecting booths at GDL, according to Jose Angel Martinez Sanchez, director of technical operations. Martinez says the product sprayed into the booth is non-toxic for humans and their belongings, is biodegradable, and has been cleared by COFEPRIS, Mexico’s Federal Committee for Protection from Sanitary Risks.

The pod contains built-in temperature sensors to check the subject for fever. The entire disinfecting and screening process takes 40 seconds.

Bottom line for flyers: leave extra time for whatever testing measures may be required, wear a mask, mind the spacing tapes, bring your own snacks, and feel free to tap frequently on the abundant hand-sanitizing stations lining airport through-flows from counter to gate. At the end of the day, no-tech and low-tech habits remain the boards and nails of the new normal.

Get Social